Slappy McTrigger

My Own Safe Space

Planning on doing this real soon possibly today. Just wondering if any of you have done this and have any advice or tips.

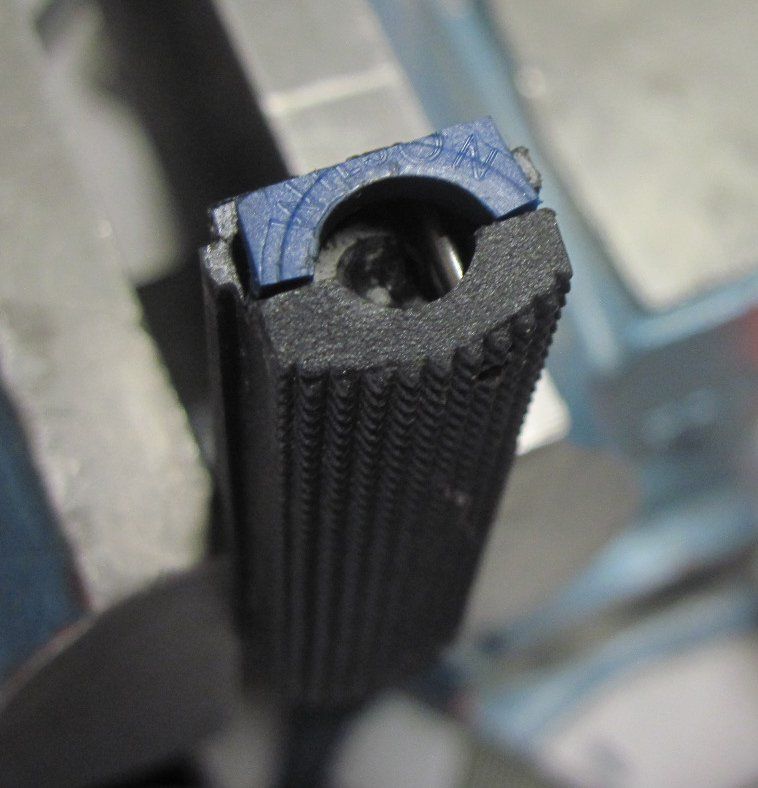

My plan is to gut the MSH, insert it with the rest of the components installed, depress the grip safety, and tap the bottom of the MSH with a plastic hammer upwards into the tangs on the grip safety. It’s a Dawson ICE aluminum part against a stainless steel grip safety so I’m hoping I can get decent witness marks. Then, with the assistance of a neighbor’s drill press, place a hole for a roll pin. This is a photo of what he set up and apparently he’s already drilled an old MSH he had laying around.

I still haven’t figured out what sized roll pin, its length, and the depth of the hole would be best so I’d be curious if anyone else out there has done something similar. I need to take the pistol down and get some measurements.

I’ve read on brazos’ site that they drill both the grip safety and the MSH but think that’s overkill. Also, not interested in filing off the lug to get around the grip safety. I’d rather have the grip safety not pivot on grip acquisition, the sear spring be fully supported, and reversible if desired.

What say you? Is this the wrong approach? Is there a better way of doing this?

This is strictly a competition gun and I have a signed permission slip from my mom for those who would never dream of doing this.

My plan is to gut the MSH, insert it with the rest of the components installed, depress the grip safety, and tap the bottom of the MSH with a plastic hammer upwards into the tangs on the grip safety. It’s a Dawson ICE aluminum part against a stainless steel grip safety so I’m hoping I can get decent witness marks. Then, with the assistance of a neighbor’s drill press, place a hole for a roll pin. This is a photo of what he set up and apparently he’s already drilled an old MSH he had laying around.

I still haven’t figured out what sized roll pin, its length, and the depth of the hole would be best so I’d be curious if anyone else out there has done something similar. I need to take the pistol down and get some measurements.

I’ve read on brazos’ site that they drill both the grip safety and the MSH but think that’s overkill. Also, not interested in filing off the lug to get around the grip safety. I’d rather have the grip safety not pivot on grip acquisition, the sear spring be fully supported, and reversible if desired.

What say you? Is this the wrong approach? Is there a better way of doing this?

This is strictly a competition gun and I have a signed permission slip from my mom for those who would never dream of doing this.