backwoodsshooter

there’s always a method to the madness

Well I kept an eye on 80% lowers. SO I finally got around to doing trying to do one on my own.

Video

Overall not bad. But still hard to beat them 30-40 anderson lowers.

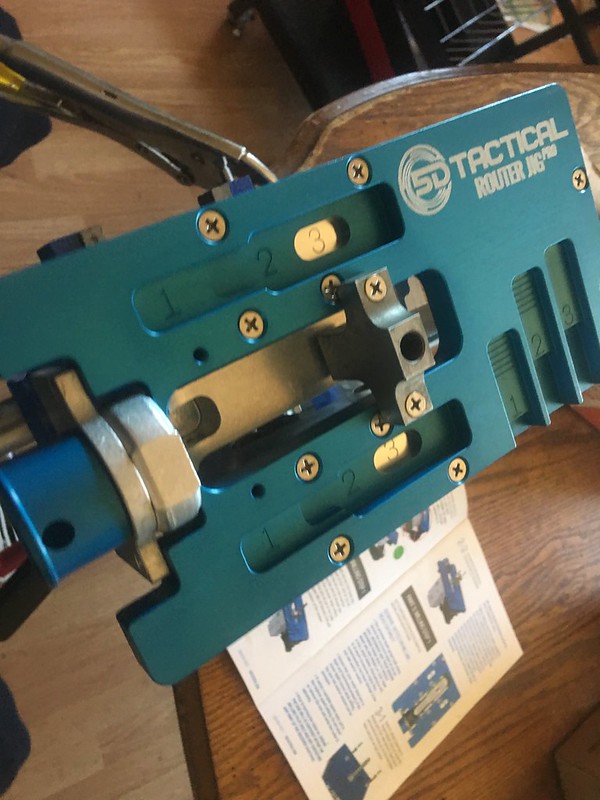

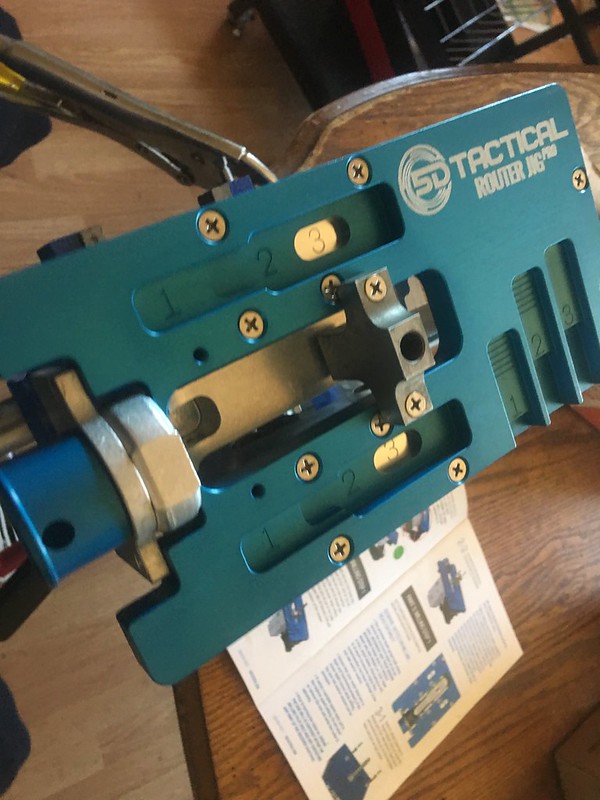

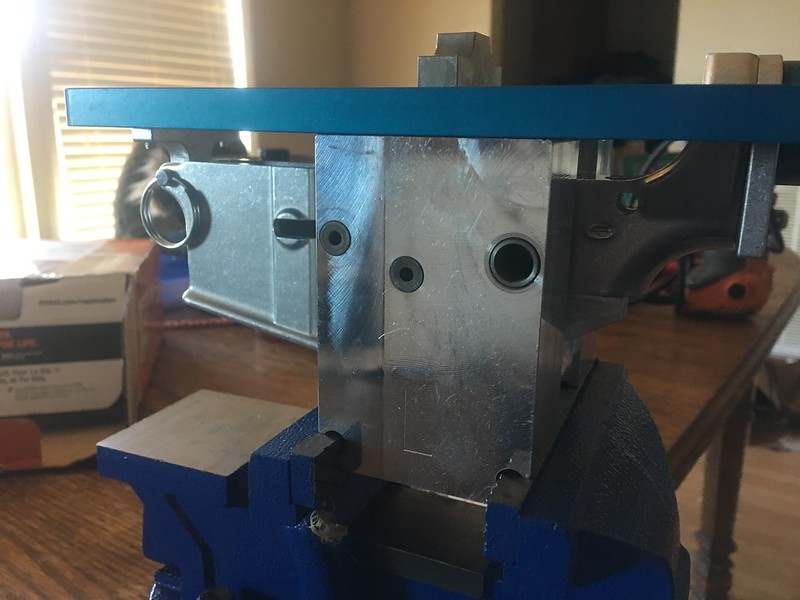

Set up was pretty straight forward and stupid simple.

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

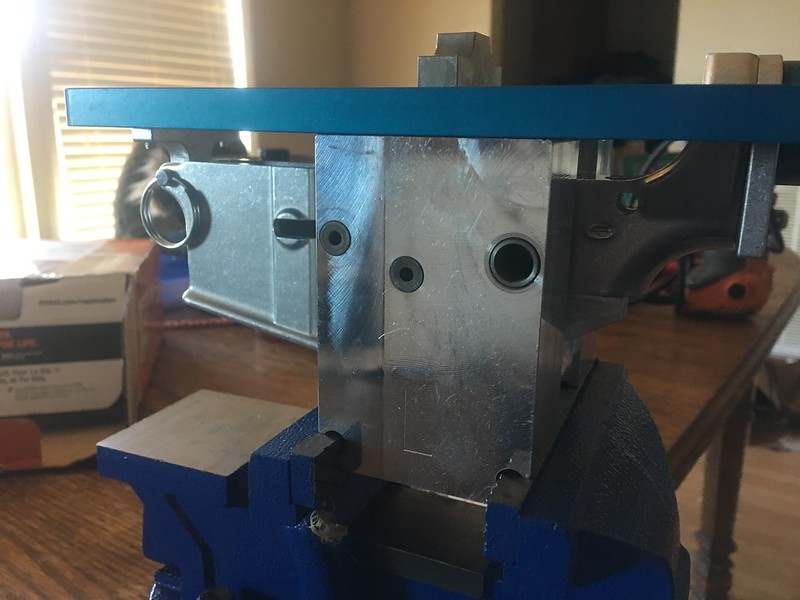

Done with the first set of cuts.

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

Second set of cuts and after the trigger pocket was milled

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

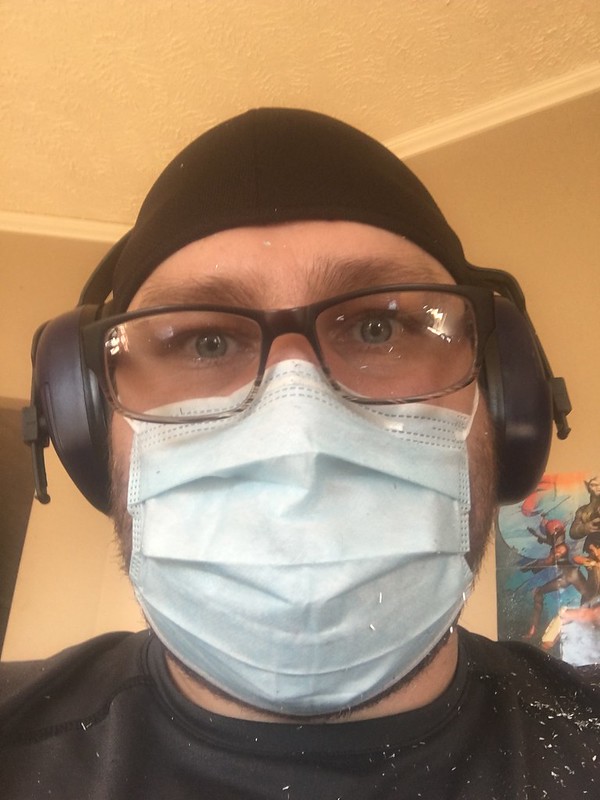

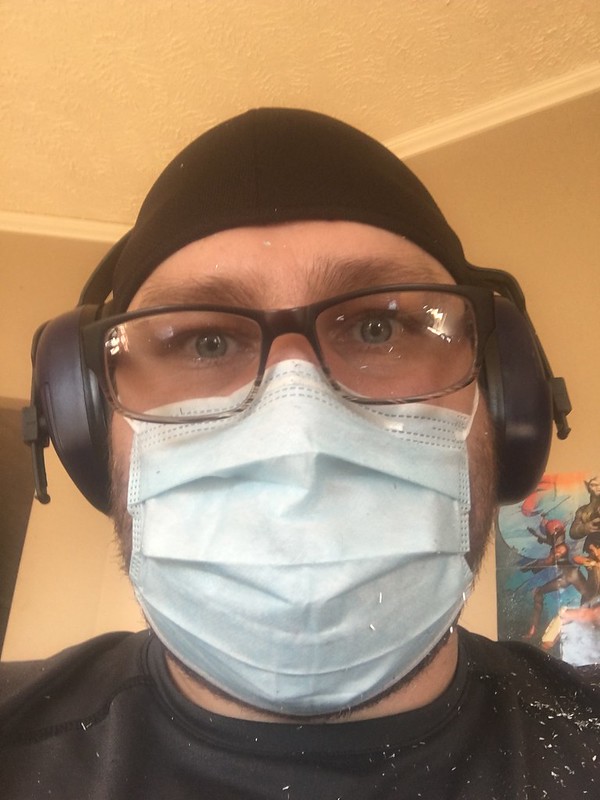

Huffing aluminum shaving and playing catch the shaving in my eyes are not fun games. Close enough PPE

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

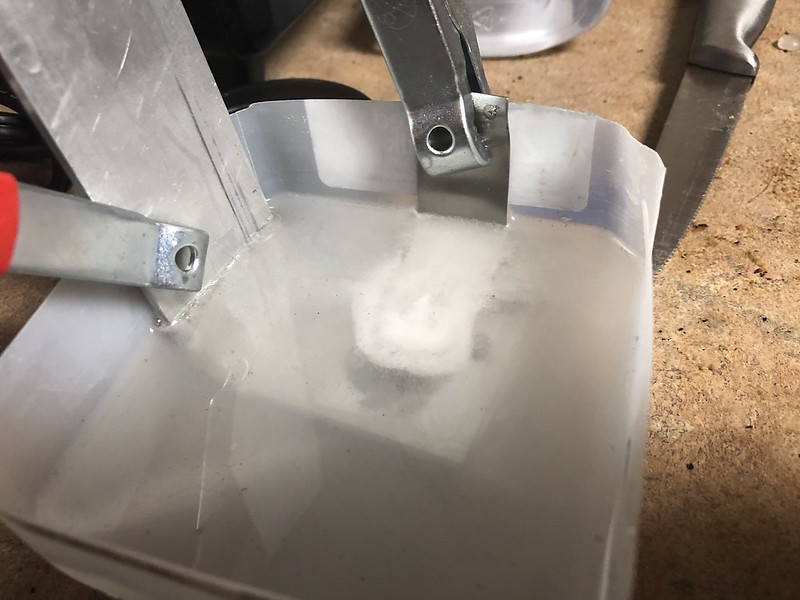

If you wanna do this, it does create a mess. Wife didn't have an issue with me doing this on the dinner table.

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

80 by Brandon S, on Flickr

80 by Brandon S, on Flickr

Done and washed.

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

Video

Overall not bad. But still hard to beat them 30-40 anderson lowers.

Set up was pretty straight forward and stupid simple.

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr Untitled by Brandon S, on Flickr

Untitled by Brandon S, on FlickrDone with the first set of cuts.

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on FlickrSecond set of cuts and after the trigger pocket was milled

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on FlickrHuffing aluminum shaving and playing catch the shaving in my eyes are not fun games. Close enough PPE

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on FlickrIf you wanna do this, it does create a mess. Wife didn't have an issue with me doing this on the dinner table.

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr 80 by Brandon S, on Flickr

80 by Brandon S, on FlickrDone and washed.

Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr Untitled by Brandon S, on Flickr

Untitled by Brandon S, on Flickr

Last edited:

Untitled

Untitled Untitled

Untitled

image1(12)

image1(12) image3(4)

image3(4) image1(13)

image1(13) image2(8)

image2(8)