Unnamed semi-custom 5-inch gun with two problems. Owner called me on a rainy Saturday afternoon.

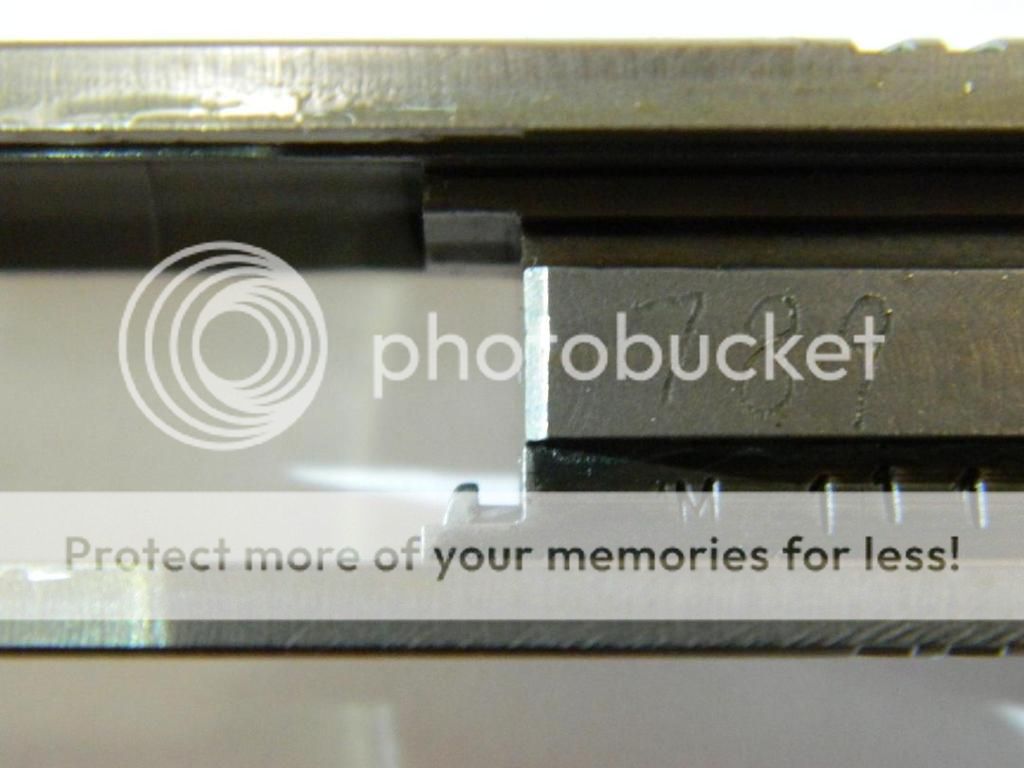

First problem was intermittent failure to go to battery. All critical frame and barrel specs were good.

Magazines not the problem.

Extractor wasn't clocking, or at least not enough to cause a problem

Owner, recognizing an issue, admitted that he had worked to try and correct the problem, and in so doing created the second without completely solving the first.

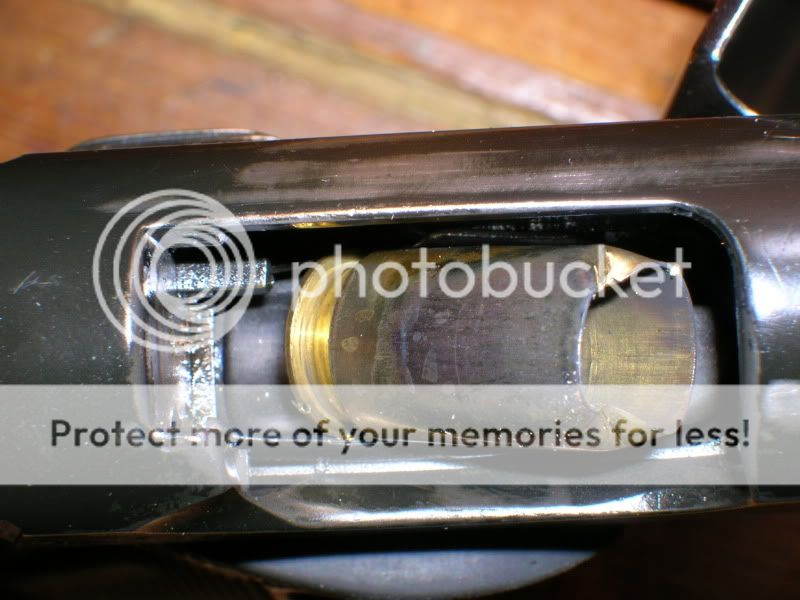

Ejection was a little erratic and weak, but acceptable...until the last round came out.

On the last round the case would be stuffed partway back into the magazine, depressing the follower and preventing the slide from locking open. Magazine forces the extractor off the case rim. Slide runs forward and tries to chamber the empty case which is sitting on a slight upward angle, and crushes the case between the breechface and the barrel hood.

This happens every time with all magazines.

Noodle it and see what you come up with.

First problem was intermittent failure to go to battery. All critical frame and barrel specs were good.

Magazines not the problem.

Extractor wasn't clocking, or at least not enough to cause a problem

Owner, recognizing an issue, admitted that he had worked to try and correct the problem, and in so doing created the second without completely solving the first.

Ejection was a little erratic and weak, but acceptable...until the last round came out.

On the last round the case would be stuffed partway back into the magazine, depressing the follower and preventing the slide from locking open. Magazine forces the extractor off the case rim. Slide runs forward and tries to chamber the empty case which is sitting on a slight upward angle, and crushes the case between the breechface and the barrel hood.

This happens every time with all magazines.

Noodle it and see what you come up with.