You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wife is going to be mad..

- Thread starter Djstorm100

- Start date

- Replies 19

- Views 1,940

Beautiful!

Those things make a LOT of chips don't they? I havent done one in a couple yrs and Im still finding the aluminum fragments in the garage.

Those things make a LOT of chips don't they? I havent done one in a couple yrs and Im still finding the aluminum fragments in the garage.

Nice !

ronn47

Where's the Scotch?

2A Bourbon Hound 2024

2A Bourbon Hound OG

Charter Member

Benefactor

Life Member

Multi-Factor Enabled

Put her mane on one and give it to her.

It's up to you if you want to make it a functional gun or not.

It's up to you if you want to make it a functional gun or not.

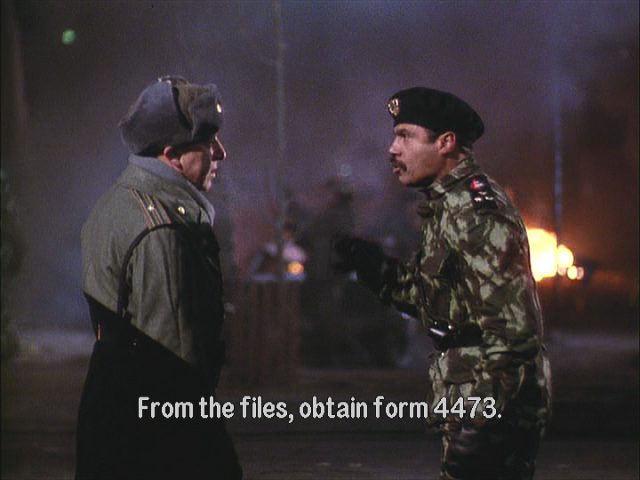

^ This is a ghost gun...

I thought about engraving Casper on the side of the magwell but resting on the side of caution. It might not do well for our cause against the left.

Although humorous, those that don't understand will assume it's kills with no mercy.

Put her mane on one and give it to her.

It's up to you if you want to make it a functional gun or not.

By ATF as soon as I remove material (even just a slot) it's consider a firearm. Going to save these for a rainy day.

I don't own an AR but can you do this with just a drill press?

Slosolo2

Here to be happy

Yes but not well.I don't own an AR but can you do this with just a drill press?

Drill press bearings are not meant to have significant side to side loads like a mill so they aren't precise and often chatter. I used an x/y vise in a drill press and it worked but was hard, slow and ended with a less than ideal product.

Thank you, yes they do. I went from 24minutes to 16, this is with doing manual tool change. Each one I made just a little bit faster with out sacrificing qualityBeautiful!

Those things make a LOT of chips don't they? I haven't done one in a couple yrs and Im still finding the aluminum fragments in the garage.

Rigid shop vac is the ticket in getting chips out. I wish I had a Haas with a convayer or arguer but have to start some where.Damn, sweep them up carefully! That many chips taken to a recycling center might yield enough money to buy another 80% “conversation piece” for future use.

You can but as other have said they won't come out as nice but still functional. they have jibs where you drill out most the material so you aren't engaging so much material on the sides.I don't own an AR but can you do this with just a drill press?

I assume you are referring to the buffer tube? If so the threads are a lower class 2 so lots of room. For the pins and safety I drill those undersize and ream them out. I can not stand loose pins.@Djstorm100

So, do you over-size the dimensions to allow for final coating, especially on the threading?

Save the chips. They have other uses.Damn, sweep them up carefully! That many chips taken to a recycling center might yield enough money to buy another 80% “conversation piece” for future use.

Sent from my SM-J320V using Tapatalk

Save the chips. They have other uses.

Sent from my SM-J320V using Tapatalk

Making fire starter?

Sent from my iPhone using Tapatalk

ronn47

Where's the Scotch?

2A Bourbon Hound 2024

2A Bourbon Hound OG

Charter Member

Benefactor

Life Member

Multi-Factor Enabled

Something like that.Making fire starter?

Sent from my iPhone using Tapatalk

Making fire starter?

Sent from my iPhone using Tapatalk

Rapid oxidation

Sent from my iPhone using Tapatalk